Sterile or Aseptic

Posted on 22nd December 2023 at 10:05

Sterile or Aseptic? Understanding the Difference

Ensuring the quality and safety of dairy and food products is the number one priority of processors, explaining why questions surrounding sterile or aseptic frequently enter into the conversation, especially when discussing equipment cleanliness and sampling or testing techniques. While the words sterile and aseptic are often used interchangeably, they are not, in fact, interchangeable. Understanding the difference is important to ensure favourable outcomes in dairy and food processing, sample collection, and laboratory testing.

What Does Sterile Mean?

In general, sterile applies to equipment and environments. It is the concept of having or using equipment that is totally germ-free. To reach this level of cleanliness, equipment must be cleaned and sanitized using specialized procedures, sterilized using validated techniques in which the ability to kill all living organisms has been tested and verified, supplied in special packaging designed to ensure maintained sterility during storage and shipping, and handled in special ways.

In medicine, for example, sterile equipment and supplies are vital to prevent contamination and infection during surgery. Similarly, sterile needles are required so patients are not infected from inoculations or during a blood draw. While the circumstances are, of course, different, the concept is the same in dairy and food processing.

When sampling and testing equipment are introduced to a process and come into contact with food, they should be sterile so there is no danger of introducing harmful bacteria or other microbes. This attention to sterility plays a critical role in upholding the quality, shelf stability, and safety of dairy and other food products and is vital for making sure samples collected from the product are free from exogenous contamination.

What Is Aseptic?

Aseptic is a term that is generally applied to techniques that keep equipment or an environment sterile. Aseptic techniques are designed to prevent the introduction or transfer of microorganisms to an environment. In other words, they keep sterile things sterile.

In a dairy or liquid food processing environment, aseptic sampling technique is critical to control contamination of either the collected samples or the food product being sampled. Aseptic techniques are required for inserting sterile sampling equipment into the production line and for collecting samples through sterile equipment. If aseptic technique is not followed, the positive effect of sterile sampling equipment is lost, collected samples may be inaccurate or become contaminated, test results will be untrustworthy, and harmful organisms may be added to products being sampled.

Aseptic Sampling Is Critical to Testing Accuracy

Dairy and food industries are vulnerable to a multitude of microbial contaminants that can compromise the quality and safety of their products. As such, the importance of proper sampling technique cannot be overemphasized. Aseptic sampling through sterile sampling equipment is critical to ensure food safety, product quality, and informed decision-making.

Agriyork400 Ltd are proud to offer aseptic sampling vials and Qualitru sampling systems.

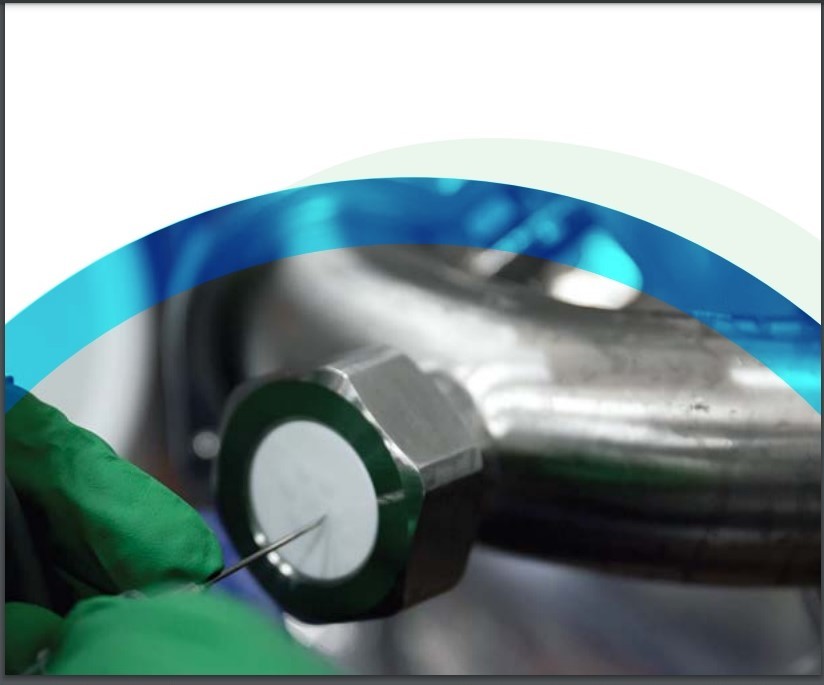

The TruStream7 Septum EU enables dairy and liquid food processors, and dairy farmers, to enhance food safety and quality processes by performing aseptic inline process monitoring simply, and cost-efficiently. Aseptic inline process monitoring, which is part of system hygiene monitoring, allows for proactive sampling and testing protocols and can enhance food quality and safety through the early identification and mitigation of in-process microbial risks.

Then complete the sampling best practice by using one of Agriyork's sampling vials.

Attached lid minimises potential contamination.

Share this post: